Guided by a sustainable business philosophy focused on ecological solutions, LCY's Water Business Unit is committed to promoting mutual environmental prosperity. LCY focuses on the development of a world-class, high-performance filtration system that utilizes cutting-edge technology for the treatment and reuse of wastewater. Our goal is to provide customers with the highest-quality membrane technology in line with global trends in water recycling.

Membrane Bioreactor

Performance

> 12,000

Cubic meter per day

As of February 2024, the daily cumulative processing volume has exceeded 12,000CMD

5

Olympic standard swimming pool

The daily cumulative processing capacity has exceeded 12,000 CMD, equivalent to 5 Olympic standard swimming pools

14

MBR collaboration projects

The MBR projects were initiated either through engineering firms or directly with clients.

Product Highlight

- From the R&D of membranes to the production of skids, everything is done domestically in Taiwan.

- MBR efficiently streamlines the water purification process and ensures optimal water quality.

- Highly customizable; the system can be tailored to create the most optimal solution

Traditional lengthy activated sludge process

LCY membrane biological reaction water filtration system

Product Description

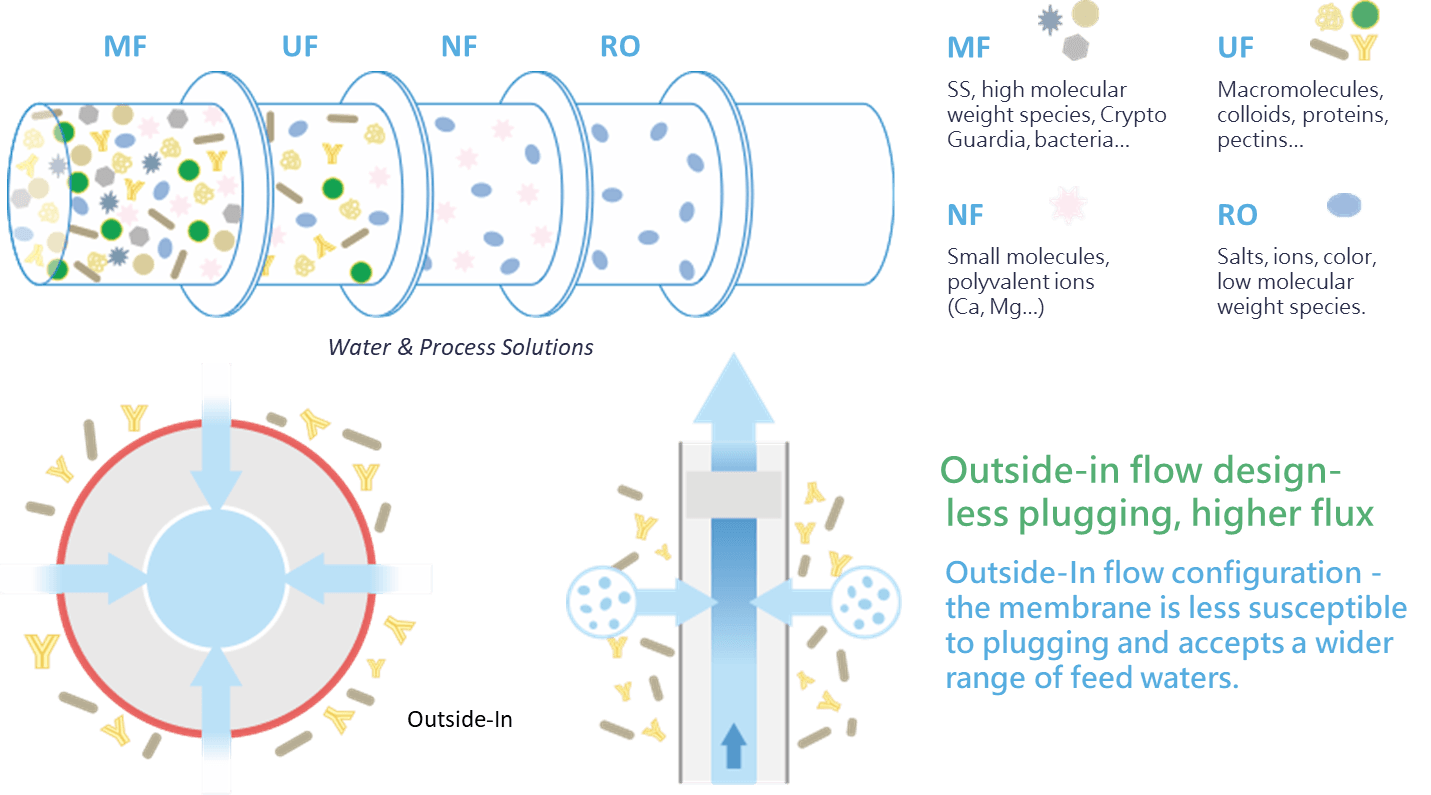

After filtering through the ultrafiltration membrane, only small molecular compounds and ions remain.

Track Record

- LCY Kaohsiung Plant, Capacity: 1000 CMD, Operation period: >8 years

- Petrochemical plant in Miaoli, Capacity: 2000 CMD, Operation period: >6 years

- Semiconductor plant in Hsinchu, Capacity: 200 CMD, Operation period: >4 years

- Memory solution plant in Taichung, Capacity: 360 CMD, Operation period: >2 years

- Biomedical plant in Hsinchu, Capacity: 100 CMD, Operation period: >3 years

- Biotechnology plant in Hsinchu, Capacity: 80 CMD, Operation period: >2 years

Product Specifications

| Grade | Operating Flux | Skid Size | Application Keywords | |

|---|---|---|---|---|

| MD345 | 15~25 | 825*56*2155 | high-performance filtration system | Add to compareAsk for sampleFiles download |

| MD245 | 15~25 | 825*56*1570 | high-performance filtration system | Add to compareAsk for sampleFiles download |

| MD146 | 15~25 | 825*56*1030 | high-performance filtration system | Add to compareAsk for sampleFiles download |